Proper welding ventilation and welding fume control are critical to ensuring worker and employee health and safety. Welding fume extraction can help limit exposure to carcinogenic fumes and other health risks, reduce employee sickness, and improve productivity.

Over the past few years, we’ve been building our knowledge base and resources on welding fume extraction, and why it’s important for the health and safety of yourself and your employees. Today we’re bundling all that together to help raise cancer awareness on World Cancer Day.

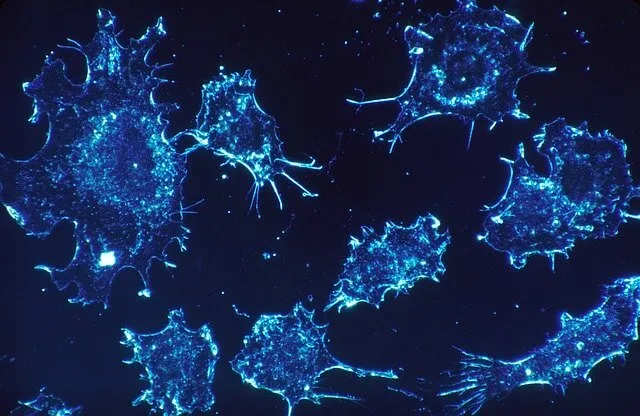

Are welding fumes carcinogenic?

There are multiple welding fume health risks. The International Agency for Research on Cancer (IARC) classifies welding fumes as a Group 1 human carcinogen, linking it to lung cancer and kidney cancer. Welding releases numerous gases, silicates, and more; Visible fume clouds are mainly metal particles, metal fluxes, or fine dust.

Chronic exposure to fumes is known to cause illness. Pneumosiderosis, or Welder’s Lung, is linked to iron dust[1]. A recent study also found that iron oxide is highly toxic to the lungs and is a key contributor to lung cancer[2].

Other metal particles can include cadmium, lead, or nickel depending on the metal and method used. For example, Chromium is produced from welding stainless steel. Chromium 6, or hexavalent chromium, is known to cause autoimmune diseases and cancer. Welders aren’t the only ones at risk; workers in the metal industry, shipyards, construction work, and transportation are also possible victims. Learn more about the health risks associated with fume particles here.

Welders have a 16% greater risk for lung cancer, 30% greater risk for kidney cancer, 40% greater risk for bladder cancer, and 78% greater risk for mesothelioma[3].

Welding fume extraction helps reduce risk of cancer

Portable fume extractors are suitable for small weld and fabrication shops, confined spaces and spaces, and situations where welding is occasional and typically light. These systems can be wheeled or carried as needed.

Mobile fume extractors are designed to be wheeled where needed and can range from light-duty, as pictured left, or medium/heavy duty, as pictured below. Mobile fume extractors are perfect for when welding rarely occurs in one static location and when central duct systems are unavailable.

Medium and heavy-duty fume extractors are available in both disposable filter models, which have lower upfront costs.

Self-cleaning models have higher upfront costs but have lower upkeep than disposable filter models.

Stationary fume extractors are wall-mounted and work well when welding occurs in static locations. These also come in light/medium/heavy-duty varieties.

Stationary fume extractors are also available with either disposable filters or self-cleaning models.

Downdraft tables are perfect for when welding is known to fit certain dimensions. Additionally, downdraft tables eliminate the need to readjust the extractor hose. These tables are suitable for welding and grinding operations.

The benefits of taking care of your workers translates to better profits

Another common welding fume health risk is metal fume fever, an occupational respiratory sickness that presents with flu-like systems due to exposure and can take 24-48 hours for symptoms to abate with full recovery taking 1 to 3 weeks. There are several reasons to ensure your business has proper welding ventilation; it can help reduce temporary workplace illnesses, improve productivity and bolster employee relations.

There are also numerous organizations and regulatory bodies dedicated to establishing standards for worker safety and health. For example, the Occupational Safety and Health Administration requires employers to provide safe working conditions and take steps to eliminate present risks.

Sources

Source [1]: Khalid, Imran et al. “A welder with pneumosiderosis: a case report.” Cases journal vol. 2 6639. 20 Apr. 2009, doi:10.1186/1757-1626-0002-0000006639 https://www.ncbi.nlm.nih.gov/pmc/articles/PMC2827098/

Source[2]: Zeidler-Erdely, Patti C et al. “Influence of welding fume metal composition on lung toxicity and tumor formation in experimental animal models.” Journal of occupational and environmental hygiene vol. 16,6 (2019): 372-377. doi:10.1080/15459624.2019.1587172 https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6538433/

Source[3]: MacLeod, Jill S et al. “Cancer Risks among Welders and Occasional Welders in a National Population-Based Cohort Study: Canadian Census Health and Environmental Cohort.” Safety and health at work vol. 8,3 (2017): 258-266. doi:10.1016/j.shaw.2016.12.001 https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5605892/

Comments are closed.