The post-2020 corporate world operates under a new imperative: what you cannot see can harm your business. Once confined to the realm of regulatory compliance, air quality has exploded into a central pillar of corporate responsibility, risk management, and employee retention.

The COVID-19 pandemic did not introduce the threat of airborne hazards; it simply forced it into sharp focus. Today, organizations are no longer just fighting welding fumes and dust; they are managing aerosol transmission and the tangible loss of productivity due to poor Indoor Environmental Quality (IEQ). This new landscape demands a decisive transition from periodic checks to Continuous Air Quality Monitoring.

From Compliance to Proactive Health Screening & Air Quality Measurement

The pandemic forced every organization to rapidly become aware of aerosol transmission; microscopic particles that can travel long distances and linger in the air. This shift had three major consequences for industrial air quality.

- The new emphasis is on capturing and monitoring particles less than 2.5 microns (PM2.5) in size. This includes welding fumes, bacteria, viruses, and other respirable crystalline silica. If your monitoring system can’t track particles this small, it can’t measure the true risk.

- The role of proper ventilation and air change rates became a recognized defense mechanism against pathogens. Safety managers realized that simply meeting fume capture standards was not enough, and they needed to understand overall room air quality between events.

- Waiting weeks for laboratory results is no longer acceptable when an instant spike in welding fume, or the presence of a viral risk, compromises the entire operation. Real-time visibility became the operational standard. Safety managers required instant data to trigger corrective action, such as adjusting a fume extraction arm or notifying maintenance of a failing filter.

The contemporary corporate landscape demands a proactive, continuous screening philosophy. The goal has shifted from simply meeting minimum compliance standards to optimizing the internal environment for human health and peak cognitive function. If you cannot measure the threat as it occurs, your safety system is obsolete.

The Critical Demand for Real-Time Air Quality Measurement

You may ask, “Why is delayed data no longer sufficient for modern operations?” This is because air quality is dynamic, not static.

In a welding shop, the momentary spike in hexavalent chromium or manganese fumes, which can occur when a capture arm is moved out of position or a door opens, must be addressed immediately, not weeks later.

Real-Time Data (RTD) provides the safety manager with an instantaneous, actionable warning system that delivers three core benefits:

- Instant Response: Alerts are triggered the moment particulate matter (especially PM2.5, which includes respirable metals and pathogens) exceeds a safe threshold, allowing staff to correct the source capture immediately.

- Proof of Performance: RTD provides an irrefutable, hour-by-hour log that the fume extraction systems were functioning correctly, dramatically simplifying compliance reporting and liability defense.

- Predictive Maintenance: Continuous monitoring of fan performance and filter saturation levels enables maintenance teams to replace filters based on actual usage and pressure drops, not an arbitrary schedule, saving costs and ensuring constant system efficacy.

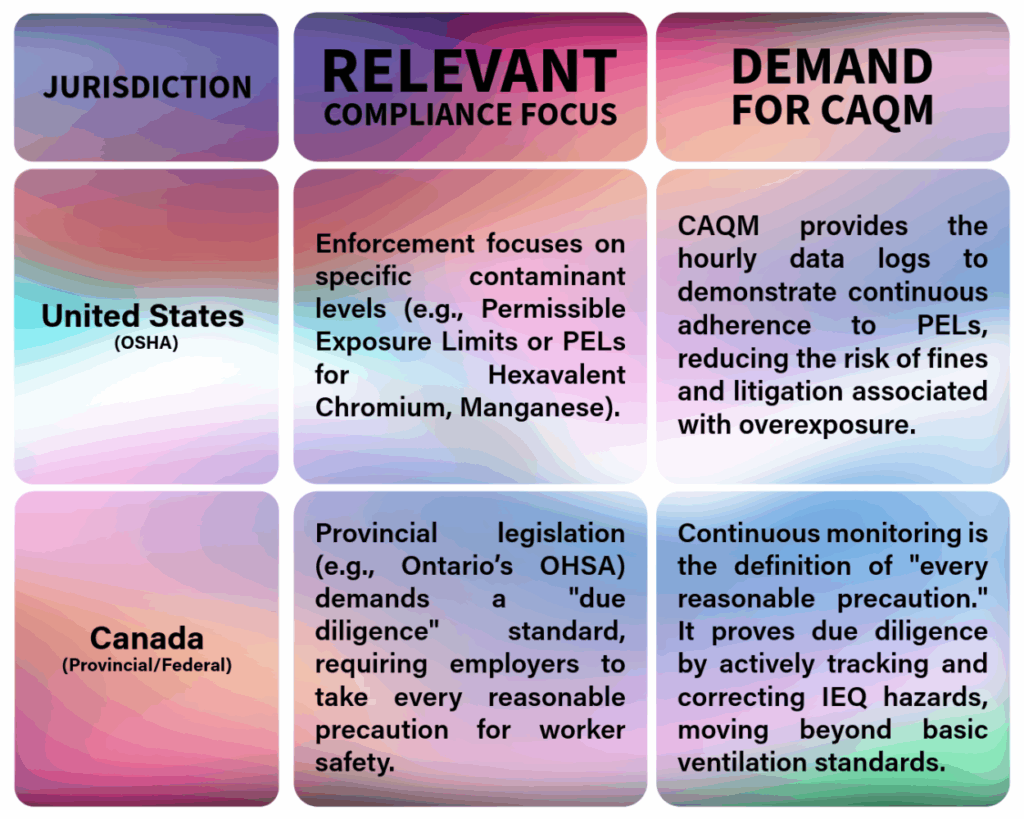

In both nations, Continuous Air Quality Monitoring is the tool that elevates a company from basic compliance to robust risk mitigation.

The Golden Age of Air Quality Measurement: The AeroGuard

The solution to the dynamic, invisible threat is the integration of the Industrial Internet of Things (IIoT) into air safety. Modern smart monitors are compact, powerful sensors that live in the workspace, constantly analyzing the air and communicating via the cloud.

These devices transition air monitoring from a slow, manual process to a proactive digital defense system. They integrate data from various sources, like:

- Temperature,

- Humidity,

- Volatile Organic Compounds (VOCs),

- Carbon Dioxide (CO2), &

- PM levels,

to give a holistic view of the workspace’s total health environment.

One such equipment is if offered by Remove The Fume, called the AeroGuard. The AeroGuard is an Industrial Air Quality Monitor engineered precisely for this new corporate landscape. It is not just a sensor; it is the early warning system that validates your entire safety investment.

The AeroGuard makes a difference in internal air quality by:

- Comprehensive PM Tracking: It focuses on the most dangerous particle sizes, ranging from PM 1 to 10 and finer aerosols, providing the intelligence needed to capture the invisible threats that compromise IEQ and long-term worker health.

- Data Validation: All performance data is logged in a centralized system, giving safety managers the verifiable proof needed to satisfy auditors and demonstrate a proactive, world-class commitment to occupational health. The historical data could be accessed by phone or by the web portal.

- Visual and Digital Alerts: Using clear signal lights and digital alerts to notify staff immediately when air quality falls short, allowing for instant corrective action.

By implementing the AeroGuard, organizations move beyond relying on faith and into a realm of verifiable safety, the true mark of a contemporary, responsible, and high-performing corporate culture.

Comments are closed.