Ensuring your workshop, facility, or welding shop has proper fume ventilation can be a daunting process. This guide to fume extraction systems will help you understand more about regulatory requirements, benefits of fume exhaust systems, types of fume ventilation systems, and some important considerations when selecting a fume extraction or fume exhaust system.

In this guide, you will find information on:

If you have any questions about fume ventilation and extraction or how we can help you, contact us today.

There are 2 types of ventilation: Local Exhaust Ventilation and Dilution Ventilation.

Local Exhaust Ventilation

Local exhaust systems remove aerial contaminants at or near the source. This offers some of the greatest protection as toxic elements are captured before they can mix with a worker’s breathing zone. This is the preferred method of fume removal if the fumes are a serious health risk, heating and cooling costs are a concern, and if there are a limited number of emission sources.

Examples of Local Exhaust Ventilation include:

- PHV (Portable High Vacuum)

- Mobile Fume Extractors

- Stationary Fume Extractors

- Downdraft Tables

- Extraction Hoods

Dilution Ventilation

Dilution ventilation aims to reduce the airborne concentration of contaminants by introducing fresh or filtered air to acceptable exposure levels. Most dilution systems will aim to “fully” cycle through the air at set intervals (e.g., 10 minutes). Larger facilities will generally adopt dilution ventilation. Combination solutions (both at-source and dilution) are also a popular choice.

Examples of Dilution Ventilation include:

Custom Solutions

Depending on the size of your facility, processes and work pieces, a custom solution may be necessary. Plymovent has a dedicated team of specialists throughout North America who will be able to assist you with facility evaluation and consultation to design a custom-tailored solution to fit your needs and goals. These systems may include both dilution ventilation and local exhaust ventilation.

Engineered Solutions

Downdraft Backdraft Table

Downdraft tables are a simple and effective source-capture fume ventilation system. Fumes are drawn down and back through a grid into exhaust ducting, preventing them from rising and mixing into the worker’s breathing zone. Downdraft tables are suitable for smaller workpieces.

The DraftMax is a work bench that comes highly recommended for intensive welding and grinding. This unit comes with a self-cleaning filter system to ensure constant and high filter efficiency. Cleaning starts automatically as soon as the fan is switched off.

-

Product on sale

DraftMax – Downdraft TableFrom USD $5,656.00

DraftMax – Downdraft TableFrom USD $5,656.00

Portable High Vacuum (PHV)

Portable high vacuum (PHV) systems are optimal for small weld and fabrication shops, maintenance facilities, and schools. Portable fume extractors are ideal solutions for confined spaces such as ship hulls and tanks, difficult-to-reach locations, or for occasional welding and fabrication projects. Portable welding fume extraction units are recommended for areas that are not accessible to stationary or larger mobile units. These units have a high degree of flexibility as they can be wall-mounted or used as a mobile unit on wheels. A HEPA filter guarantees high filtration efficiency and makes the PHV suitable for stainless steel welding, as the HEPA filter comes standard with the unit.

-

PHV – Portable Fume ExtractorUSD $1,485.00

PHV – Portable Fume ExtractorUSD $1,485.00

Mobile Fume Extractors

Mobile welding fume extraction systems are designed to be wheeled around facilities as needed to sources of pollution without a fixed location. Mobile fume extraction units can come in light, medium, or heavy-duty variants. Medium and heavy-duty mobile systems are available with disposable filters or self-cleaning filters.

Mobile Fume Extractors – MobileGo

The MobileGo is designed as an entry level mobile fume extraction system for welding processes. This unit comes standard with a KUA extraction arm and can be used in steel and stainless welding applications.

-

MobileGo – Mobile Fume ExtractorFrom USD $2,835.00

MobileGo – Mobile Fume ExtractorFrom USD $2,835.00

Mobile Fume Extractors – MFD (Disposable) / MFS (Self-Cleaning)

The MFD/MFS are mobile fume extractors, designed to remove dry welding fumes near the source. These mobile units contain a mechanical DuraFilter system and come standard with the UltraFlex extraction arm. The MFD and MFS come standard equipped with a filter indicator which shows whether the filter needs to be replaced.

-

MFD – Mobile Fume Extractor (disposable filter)From USD $4,125.00

MFD – Mobile Fume Extractor (disposable filter)From USD $4,125.00 -

MFS – Mobile Fume Extractor (self-cleaning filter)From USD $5,705.00

MFS – Mobile Fume Extractor (self-cleaning filter)From USD $5,705.00

Mobile Fume Extractors – MobilePro

The MobilePro is a self-cleaning fume extractor designed for professional welders. The MobilePro is suitable for a variety of welding applications, such as: MIG, MAG, TIG, GMAW, FCAW, and stick electrode welding. A SilentFlow duct free silencer reduces both the mechanical and airflow noise of the fan.

Self-cleaning is done with the Ram-Air pulse amplifier, which enhances cleaning efficiency. The Ram-Air pulse amplifier is placed within the filter cartridge and disperses pulsed energy directly to the filter medium. This results in cleaner filters, lower pressure drop, less compressed air and energy consumption.

The filter for the MobilePro is Plymovent’s BiCo polyester filter. The BiCo polyester filter guarantees consistent quality, strength, and longer filter life. As these filters are 100% polyester, they are also washable.

-

MobilePro – Mobile Fume ExtractorFrom USD $4,125.00

MobilePro – Mobile Fume ExtractorFrom USD $4,125.00

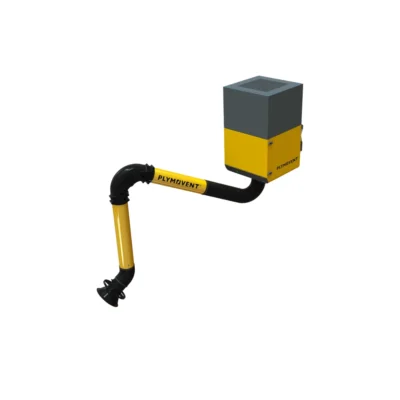

Stationary Fume Extractors

Stationary systems save on valuable floor space by being attached to the walls of a facility. Stationary fume extraction units can come in light or heavy-duty variants. Heavy-duty mobile systems are available with disposable filters or self-cleaning filters.

-

DualGo – Stationary Fume ExtractorFrom USD $4,420.00

DualGo – Stationary Fume ExtractorFrom USD $4,420.00 -

MonoGo – Stationary Fume ExtractorFrom USD $3,125.00

MonoGo – Stationary Fume ExtractorFrom USD $3,125.00 -

Product on sale

SFD – Stationary Fume Extractor (disposable filter)From USD $3,200.00

SFD – Stationary Fume Extractor (disposable filter)From USD $3,200.00 -

Product on sale

SFS – Stationary Fume Extractor (self-cleaning filter)From USD $5,140.00

SFS – Stationary Fume Extractor (self-cleaning filter)From USD $5,140.00

Types of Fume Extraction Ventilation Systems

Diluter Systems

Diluter systems are an option when at source extraction may not be practical. These stand-alone systems are typically used in large workshops where crane transportation is present, and ductwork is difficult to install. Diluters continuously filter and recirculate cleaned air into workshops to control welding fume concentration levels. Diluters are commonly used in conjunction with local fume ventilation systems as part of a complete welding shop ventilation system.

Extraction Hoods

Extraction hoods, or fume hoods, are ideal for robotic welding cells. These systems can also be used when welding is confined to a specific area. Plymovent FlexHoods are modular extraction hoods that can be ceiling mounted or held by standards. Extraction hoods will capture rising fumes and into your filtration system before they mix with your facility’s general atmosphere. Extraction hoods are common in facilities with robotic welding as part of their welding shop ventilation system.

Multiple Arm Systems

Larger facilities with a row of welding booths can still benefit from source extraction. A multiple arm system allows for individual positioning where needed. When outfitted with automatic control systems, they also reduce energy consumption providing a faster recovery of investment. Multiple arm systems are commonly found in larger welding shop ventilation systems.

Regulations

One of the most important things to keep in mind is local, regional, or national regulations. Regulatory bodies will often provide guidance, exposure limits, and training. Failing to meet your local regulations can be costly for businesses as you may face fines or lawsuits in the long term. Additionally, short-term costs may arise from lost productivity as workers face illnesses such as metal fume fever.

Below, you’ll find a list of some resources to help you learn more.

Benefits

There are numerous benefits to invest in a fume extraction system.

Productivity

Proper fume extraction can help reduce employee sicknesses such as metal fume fever. Demonstrating a commitment to employee health and well-being will also help attract and retain a highly-skilled workforce.

Keeping your facility free of contaminated air and dust particles decreases maintenance downtime and reduces the risk of fires or explosions.

Legality

Strict rules and regulations exist to protect employees and ensure a safe working environment. A well-designed fume extraction system installed in your facility can help ensure you meet these requirements and regulations.

Fume Extraction System Considerations

Now you know some of the regulations and benefits of proper fume ventilation and want to purchase a fume extraction system. Where do you start? How do you start?

An excellent starting point is understanding your facility and needs.

- How big is the workshop or facility?

- How much welding is done?

- How many welders are there?

- Is there a robotic welder?

- Does metalwork occur in specific, pre-defined locations?

- How much floor and wall space is there?

How to Choose a Fume Extraction System

You know that it’s important to capture toxic particulate from weld fumes before you can breathe it in. But what if you or your welders are moving around and a stationary unit doesn’t have the reach or coverage for your work?

Portable and mobile fume extractors are an excellent solution when factory space is limited, budgets are limited or welding tasks don’t require large fume extraction units.

Larger facilities with heavy welding operations might require a more in-depth solution. Extraction hoods could be used for areas where regular welding occurs. If a duct system is not available, other systems might be used such as a diluter system.

Below, you’ll find some additional considerations when choosing a fume extraction system.

Filter

- The filter is one of the most important factors to consider when buying a fume extraction system.

- Choose a fume extraction system and filter that is specific to your need. Many filters are not designed to collect the carcinogenic particles found in welding fumes.

- The size of hexavalent chromium particles from welding is typically between 0.05 to 2.0 microns.

- When working with stainless steel, a high-efficiency filter is recommended. High-efficiency filters can be found in the MFD or MFS mobile fume extractor, the SFD or SFS mobile fume extractor.

- A combination of filters may be used to improve air quality. The MobilePro is a welding fume extraction system available with HEPA after filters.

- HEPA filters are the gold standard when it comes to air filtration and can capture up to 99.995% of particles.

Airflow

All fume extraction systems are rated based on the amount of cubic feet of air they circulate each minute (CFM). There are multiple factors which may affect an extractor’s CFM, even when brand new. For optimal results, consult a fume extraction system manufacturer to determine the best extraction system for your needs.

Disposable or Self-Cleaning Fume Extractors

Fume extraction systems are either disposable or self-cleaning units. Disposable units use filters that are discarded as they reach capacity. A self-cleaning filter may be used multiple times, since particles may be cleaned from the filter’s surface.

Each of these units has its benefits. Mobile and stationary extractors can come in both disposable and self-cleaning models.

- Disposable models have lower initial costs but will require regularly replacing filters.

- Self-cleaning models have higher initial costs but will provide cost savings as their filters are reusable.

Flexibility

In some shops, flexibility is required and welders would benefit from a variety of units that are capable of adapting to the rapidly changing nature of their work.

Fixed systems might not be useful in smaller shops where welding operations move around regularly. Similarly, a heavy-duty system might not be useful for a shop where there are only occasional welding activities.

User Experience

An often overlooked aspect in selecting a fume extraction system is the ancillary quality of life improvements. For example, ensuring the user interface is easily understandable will help to keep operations flowing smoothly. The accessibility of components and duration required for filter replacement and cleaning are all important considerations as well.

Contact us for a consultation to find out how we can help with your fume extraction ventilation needs, keep you and your workers healthy, your equipment running more efficiently, reduce downtime and boost profits.

Comments are closed.