The image of a welder, shrouded in sparks and smoke, wielding their torch with practiced ease, is as iconic as the industry itself. But behind this image lies a hidden danger: the constant threat of exposure to welding fumes. These fumes, a noxious cocktail of gases and particles, pose a serious health risk to welders, potentially leading to a range of debilitating illnesses.

In this article, we’ll explore the essential role of fume extractors in protecting welders’ health. We’ll delve into the dangers of welding fumes, the benefits of using a fume extractor, and the different types of extractors available to suit various welding environments. By the end, you’ll understand why a fume extractor is not just another tool – it’s the most important investment a welder can make in their long-term health and well-being.

The Invisible Threat: Understanding Welding Fumes

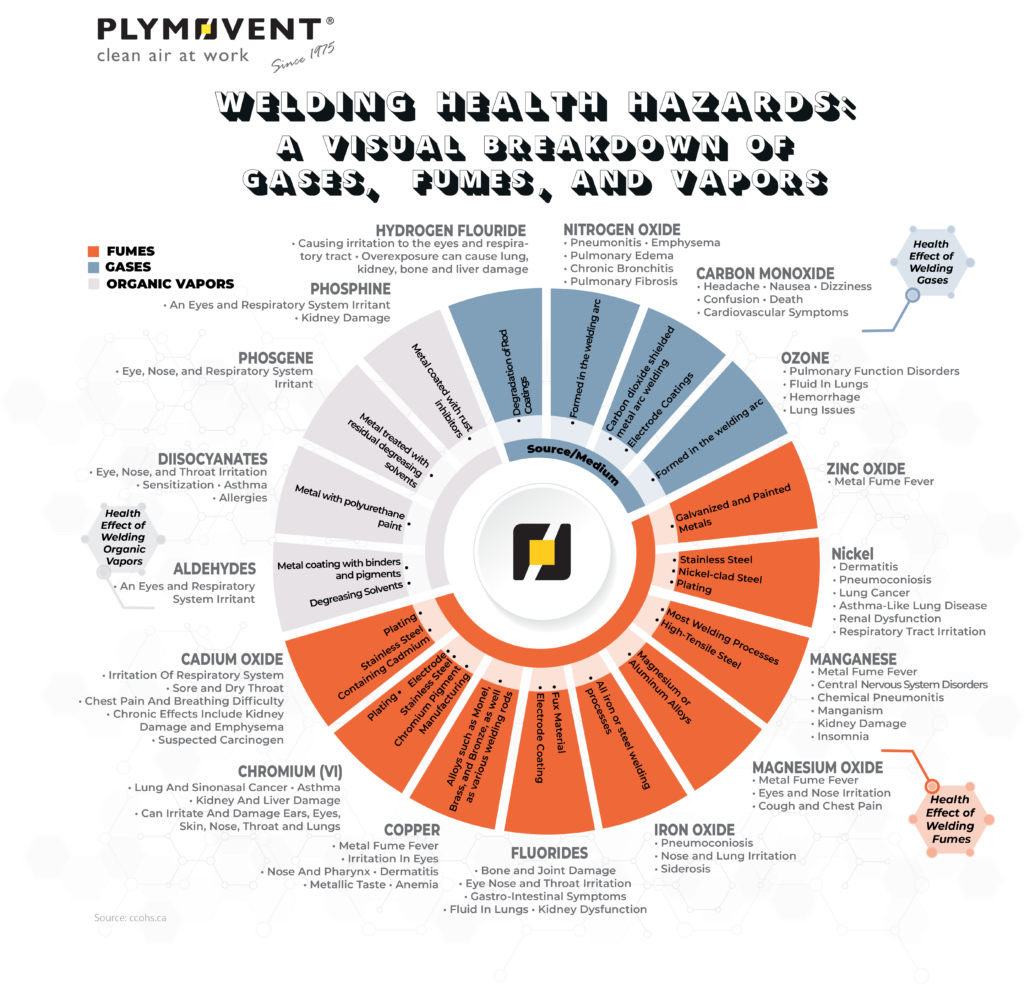

The welding process generates a complex mixture of fumes and gases. These fumes can arise from the base metal being welded, the filler metal used (electrodes, welding rods), and any coatings or contaminants present on the metal surface. Here’s a breakdown of the key components:

- Metal Oxides: When metals are heated to high temperatures during welding, they react with oxygen in the air to form metal oxides. These oxides, particularly those of manganese, chromium, and nickel, are highly hazardous when inhaled.

- Gases: Welding can produce various gases depending on the type of welding process used. These gases can include ozone, carbon monoxide, nitrogen oxides, and fluorides, all of which can irritate the respiratory system and cause other health problems.

- Volatile Organic Compounds (VOCs): Some coatings and paints on metals can release VOCs when heated during welding. These VOCs can irritate the eyes, nose, and throat, and may have additional health effects depending on the specific compounds involved.

The size and composition of welding fumes vary depending on the specific welding process, materials used, and welding parameters. However, the potential health risks remain constant.

The Silent Enemy: Health Risks of Welding Fume Exposure

Inhaling welding fumes can have a wide range of detrimental effects on your health, both immediate and long-term. Here’s a closer look at some of the potential consequences:

- Metal Fume Fever: This flu-like illness can develop within hours of exposure to high levels of metal oxides, particularly those of zinc or copper. Symptoms include chills, fever, nausea, and muscle aches.

- Respiratory Problems: Chronic exposure to welding fumes can irritate and inflame the respiratory system, leading to conditions like bronchitis and asthma.

- Pneumonitis: In severe cases, exposure to welding fumes can cause inflammation of the lungs (pneumonitis).

- Cancer: Several studies have linked long-term exposure to welding fumes with an increased risk of lung cancer.

- Other Health Issues: Welding fumes have also been linked to neurological problems, kidney damage, and heart disease.

These are just some of the potential health risks associated with welding fume exposure. The severity of these effects depends on various factors, including the type and amount of fumes inhaled, the duration of exposure, and individual health factors.

The Guardian in the Smoke: How Fume Extractors Protect Welders

Fume extractors, also known as welding fume collectors, are designed to capture these harmful fumes and gases at the source, significantly reducing a welder’s exposure. Exploring the Options: Different Types of Fume Extractors.

- Downdraft Tables: Downdraft tables provide an integrated solution for capturing and removing contaminants generated during benchtop work, ensuring a cleaner and safer working environment with efficient ventilation at the source.

- Mobile Fume Extractors: Mobile fume extractors offer portable and efficient solutions for capturing and removing harmful fumes and particles from various work areas, promoting safer and healthier environments on the go.

- Extraction Arms: Extraction arms are flexible, precision tools designed to capture and remove airborne contaminants at the source, ensuring cleaner and safer working environments.

- Stationary Extractors: Stationary fume extractors provide reliable and efficient ventilation solutions for fixed workspaces, ensuring clean air and a safe environment

- Diluter System: Diluter systems offer effective air purification by diluting and removing contaminants from indoor environments, promoting healthier air quality. By effectively capturing and filtering welding fumes, fume extractors create a safer and healthier working environment for welders.

- Reduced Health Risks: The primary benefit of using a fume extractor is the significant reduction in a welder’s exposure to harmful fumes and gases. This can help to prevent the development of various health problems associated with long-term exposure.

- Improved Visibility: Welding fumes can significantly obstruct your view of the weld pool and surrounding area. A fume extractor creates a clearer working environment, allowing for greater precision and better-quality welds.

- Enhanced Productivity: Working in a smoke-filled environment can be uncomfortable and distracting. Fume extractors help to remove smoke and improve air quality, leading to increased comfort and potentially.

Comments are closed.